Experience the Power of Quality Steel Rolls

+91 98769-00096

info@didarsteel.com

Experience the Power of Quality Steel Rolls

+91 98769-00096

info@didarsteel.com

Double Poured Alloy Indefinite

Double Poured Alloy Indefinite

Didar Steels

Double Poured Alloy Indefinite

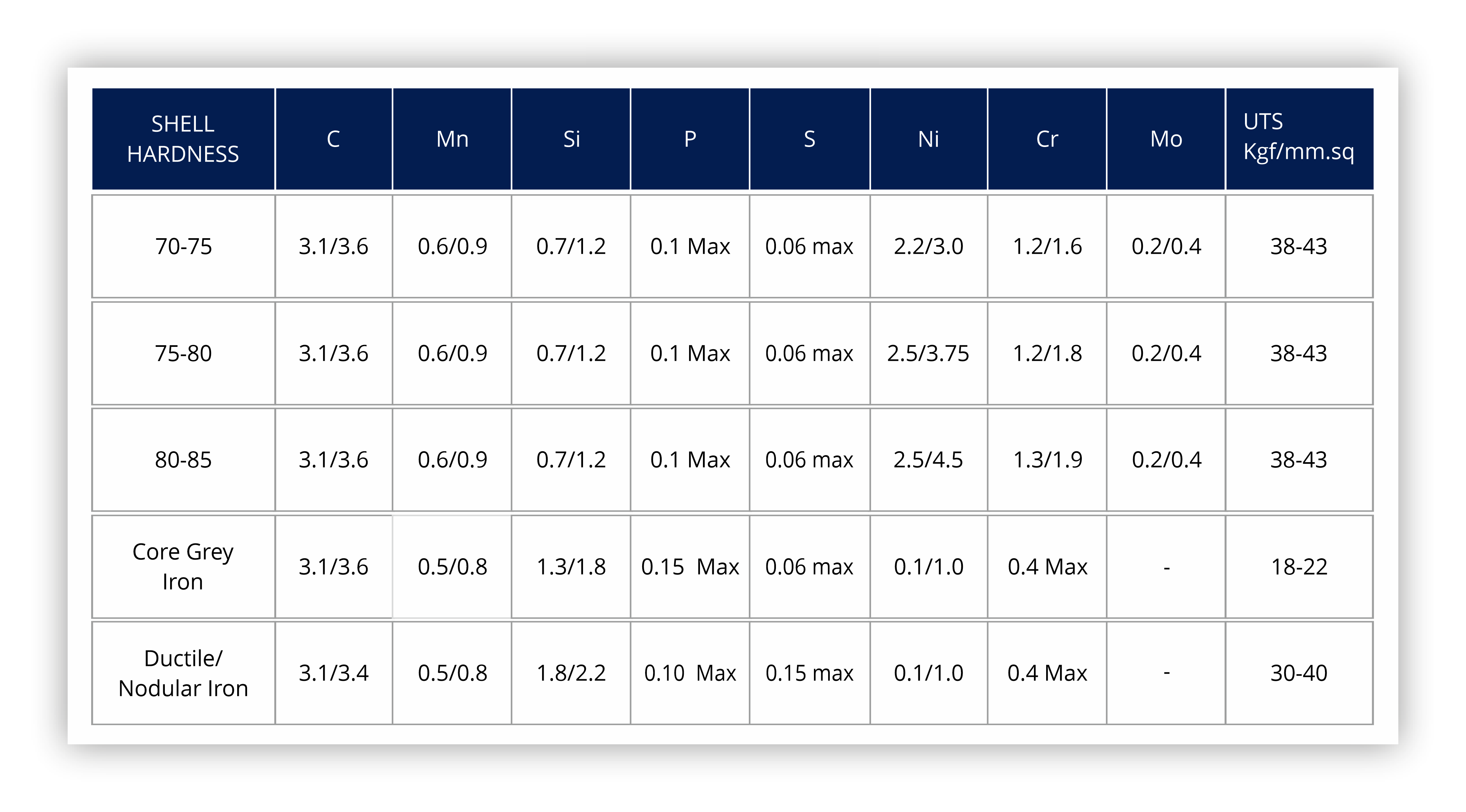

Rolls are a critical component in the rolling process, and high-quality rolls are essential for achieving efficient and reliable production. The rolls made of high alloy iron shells with grey or ductile iron core metal are a popular choice for finishing stands of rod mills and flat rolling applications. The shell material, consisting of a predominantly bainitic or martensitic matrix with free carbides and small quantities of flake graphite, offers exceptional wear resistance and fire-cracking resistance. These rolls have a hardness range of 70 to 85 Shore C, making them highly durable and long-lasting. The core material is mostly grey iron, but where additional strength is required, the core is made of ductile/nodular cast iron. These rolls provide an excellent balance of strength, wear resistance, and fire-cracking resistance, making them an ideal choice for a wide range of rolling applications.