Precision, Quality, and Excellence in Steel Rolling - Didar Steel Complex Pvt. Ltd

year experience

Industries Served

Factories Built

25+

Years Experience

36

Industries Served

105

Factories

Built

We are committed to provide safe industrial solutions to many factories

Consectetur adipisicing elit sed do eiusmod tempor dolor magna aliquat enim veniam quis nostrud exercitation ullamco consequat.

Lorem ipsum dolor sit amet, consectetur adipisicing elit sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis node trud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit.

Years Experience

Industries Served

Factories Built

Get High-Quality Steel Rolls

Our Team

100+ skilled professionals and engineers with advanced machinery.

Experienced

The team members have considerable knowledge and proficiency in their respective fields.

Skilled

The team members have developed and refined specific abilities and competencies.

Professional

The team members conduct themselves in a competent, ethical, and respectful manner.

Dedicated

The team members are committed and enthusiastic about achieving the company’s goals.

Collaborative

The team members work effectively and efficiently together to achieve common objectives.

Innovative

The team members are creative and forward-thinking, and they seek out new and improved ways of doing things

Experienced

The team members have considerable knowledge and proficiency in their respective fields.

Skilled

The team members have developed and refined specific abilities and competencies.

Professional

The team members conduct themselves in a competent, ethical, and respectful manner.

Dedicated

The team members are committed and enthusiastic about achieving the company’s goals.

Collaborative

The team members work effectively and efficiently together to achieve common objectives.

Innovative

The team members are creative and forward-thinking, and they seek out new and improved ways of doing things

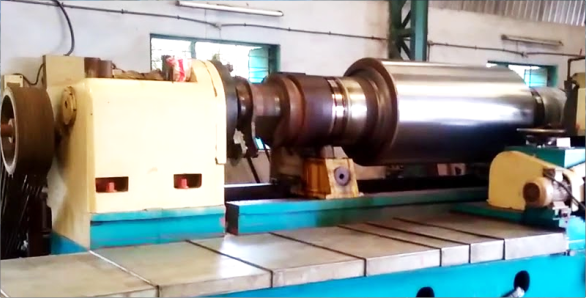

Infrastructure

-

Refining Ladled: High-quality steel production through a refining process.

-

Accurate responses to client’s requirments

-

Capacity 10 MT./ 8MT /5MT: Ability to produce large amounts of steel rolls.

-

E.O.T. Crane's 15MT/30MT max lifting capacity: Heavy-duty cranes for lifting and transporting steel rolls.

-

Generator Set: Power backup to ensure continuous production.

-

Temperature Recorders for LM, temperature measurement, Argon Purging System, Ferroalloys Preheating System: Advanced systems to maintain precise temperature and quality control.

-

Ferro Lab for carbon equivalent measurement: Lab equipped for measuring carbon equivalent to ensure high-quality steel production.

Infrastructure

-

Refining Ladled: High-quality steel production through a refining process.

-

Accurate responses to client’s requirments

-

Capacity 10 MT./ 8MT /5MT: Ability to produce large amounts of steel rolls.

-

E.O.T. Crane's 15MT/30MT max lifting capacity: Heavy-duty cranes for lifting and transporting steel rolls.

-

Generator Set: Power backup to ensure continuous production.

-

Temperature Recorders for LM, temperature measurement, Argon Purging System, Ferroalloys Preheating System: Advanced systems to maintain precise temperature and quality control.

-

Ferro Lab for carbon equivalent measurement: Lab equipped for measuring carbon equivalent to ensure high-quality steel production.

Quality Assurance

- Fully equipped wet analysis chemical lab for accurate chemical analysis of steel.

- Ultrasonic Flaw Detector for detecting internal and surface defects in steel.

- Muffle Furnace for precise and consistent heat treatment.

- Hardness Testing Equipment to ensure that the steel meets the required hardness.

- Universal Testing Machine to test the mechanical properties of steel, including tensile strength, yield strength, and elongation.

- Sand Testing Lab for analyzing the quality of sand used in the production of steel.

- Impact Testing Machine to test the impact resistance of steel.

- Sample Cutting Machine for obtaining precise samples for testing.

- Marking Instruments for permanent and accurate marking of steel products.

- Metallurgical Microscope X-1000 with photography facility for microstructural analysis.

- Ultrasonic Testing for detecting internal and surface defects in steel.

- Magnetic Particle Testing and Die Penetration Testing for detecting surface defects in steel.

- At Didar Steel Complex Pvt. Ltd., we take our commitment to quality seriously and use these advanced testing facilities and equipment to ensure that our customers receive high-quality steel products that meet their exact requirements.